We have developed our production system so that we can also apply it on the walls and inside the houses to give beauty and elegance, as it has many advantages over the regular plastering system

1 - cost is low

compared to the regular system Where cement is applied and after drying the surface is treated to soften and paint so it needs several stages. Our product is applied in one stage, there is no need for a later coating to cover the color of the cement, because our product is applied and colored once according to the customer’s desire. .

2

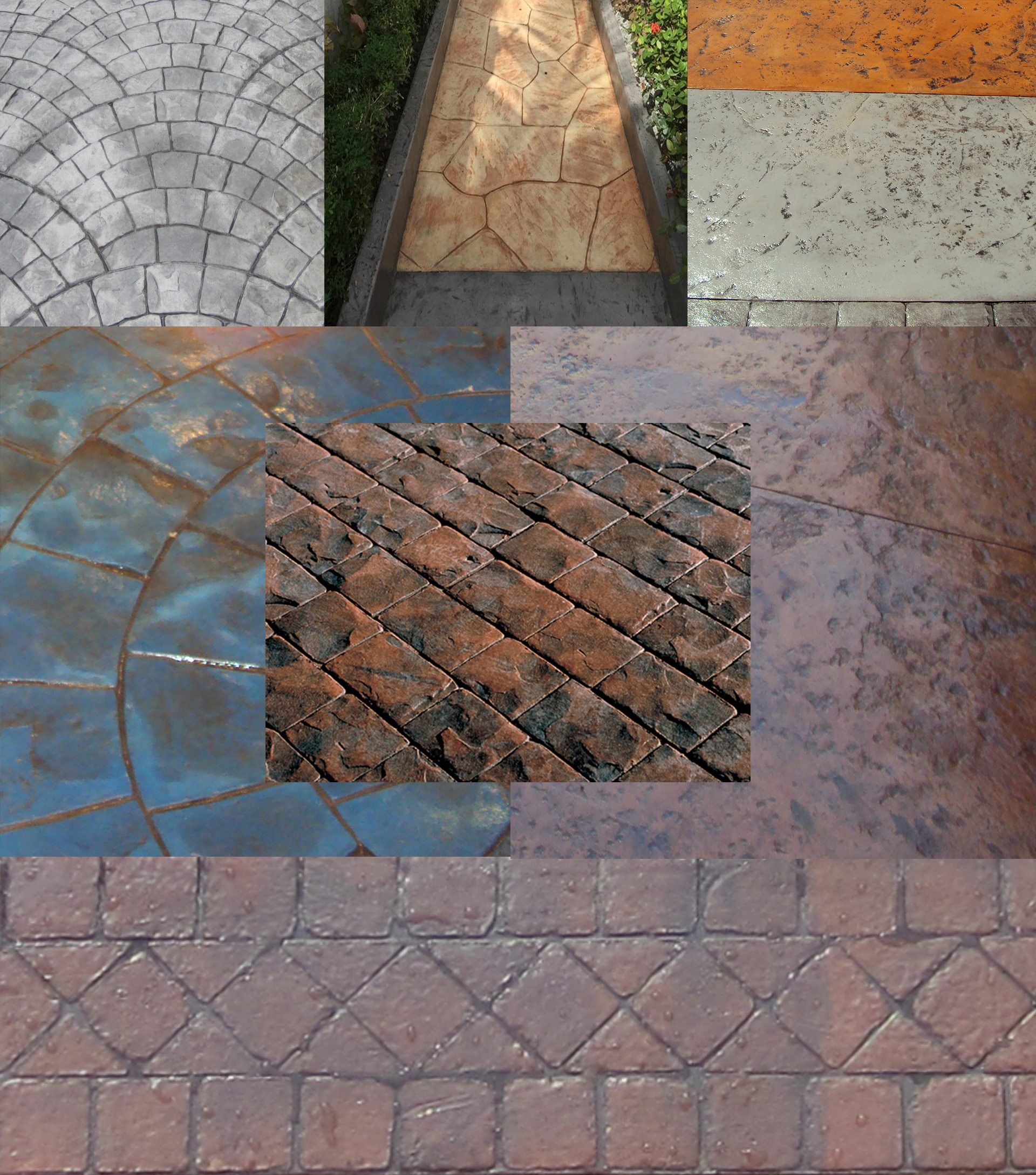

Our collection includes many beautiful and modern designs, so we can introduce any design chosen by the customer and even merge several designs in different colors from a variety of existing forms we have.

3 - high adhesion ability

In addition to the use of hardener color, we also add materials that increase the adhesion of color to avoid any peeling in the surface in addition to the use of an iron mash thickness of 1 mm within the cement to achieve greater cohesion in the surface of the cement to no cracks appear on the surface after.

4

Our product is finished with plastic transparent materials, this insulation material is completely waterproof to prevent water from reaching the color layer and thus prevent future color change, this layer also works to penetrate the pores of color and cement to achieve the greatest durability of color and cement surface